Bleed Feed Valves

A Bleed/Feed valve acts as a 3-way, 3-position, closed center control valve, with two solenoid operators. As you can see from the pictures to the right, the Bleed/Feed valve is essentially two DASH 1 valves that have been mounted together with special porting, depending on customer requirements.

Choose your option

DASH 1 Valves

The DASH 1 valve family is based on a direct solenoid poppet that can be either a three way (3/2) or a two way (2/2) valve. The DASH 1 is a precision combination of miniature size, fast response, high flow, low power, and long life.

There are several valve versions in the DASH 1 family. Cataloged models include: ports in body, manifold mount, adapter plate, PC board mount, and 1/8 pipe-stud output.

Choose your option

DASH 2 Valves

There are no moving seals in the DASH 2 valve! The DASH 2 is a metal to metal lapped spool valve. Traditional metal to metal valves can be unforgiving and require extremely fine filtration. Dynamco’s design of using dissimilar metals of different hardnesses eliminates the need.

Dynamco controls the clearances between the body and spool by individually match fitting each spool and body to achieve a proper floating air bearing. The clearance has a narrow range that every valve must achieve. The thermal expansion coefficients of the body and spool are the same so the clearance stays the same over a wide range of temperatures.

Choose your option

DASH 3 Valves

There are no moving seals in the DASH 3 valve! The DASH 3 is a metal to metal lapped spool valve. Traditional metal to metal valves can be unforgiving and require extremely fine filtration. Dynamco’s design of using dissimilar metals of different hardnesses eliminates the need.

Dynamco controls the clearances between the body and spool by individually match fitting each spool and body to achieve a proper floating air bearing. The clearance has a narrow range that every valve must achieve. The thermal expansion coefficients of the body and spool are the same so the clearance stays the same over a wide range of temperatures.

Choose your option

Pneumatic Fittings

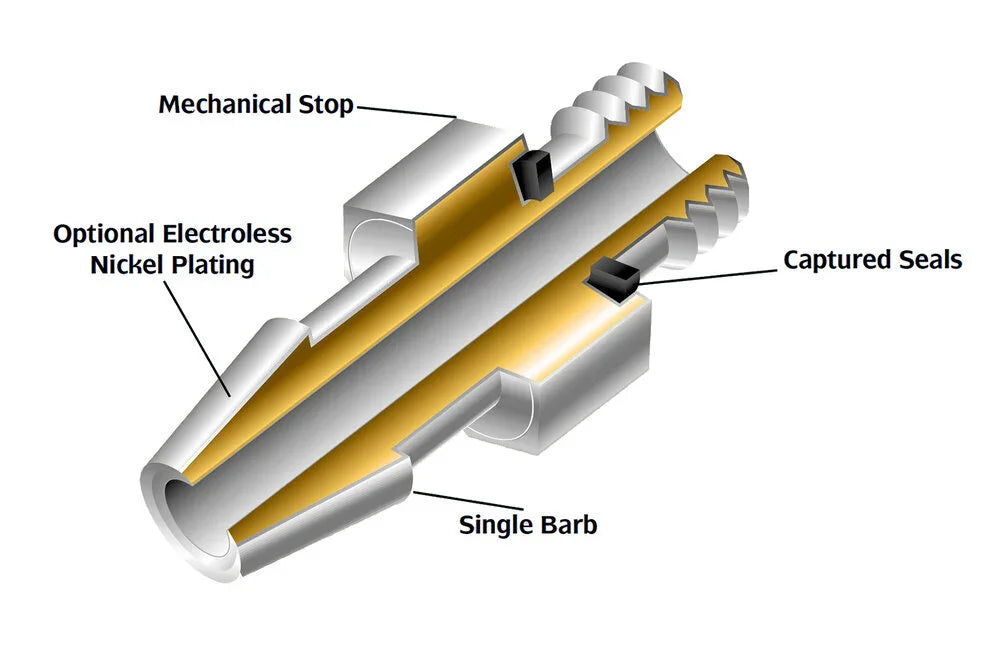

Captured Seals – Dynamco fittings have their seals already installed on the fitting thread. This feature offers significant time savings, eliminating the need to install seals upon receipt or during installation.

Mechanical Stop – The thread and seal design allows the user to tighten the fitting (5.5 in–lb ± 0.5) without cutting or damaging the seal. This seal “squeeze” is controlled by the undercut cavity, allowing the seal to be used an infinite number of times, without wear or damage.

Single Barb – The tapered nose of Dynamco's single barb fitting eases installation, but also ensures more positive sealing and holding of pneumatic tubing.

Electroless Nickel Plating – While standard brass fittings work in most applications, several Dynamco fittings are now available with electroless nickel plating. This catalog outlines where plating is offered as an option by listing a “P” at the beginning of the part number.

Stainless Steel Check Valves & Flow Controls – Dynamco's check valves and flow controls are now also available in Stainless Steel.

Elimination of Unnecessary Fittings – It is possible, in many cases, to replace two ordinary fittings with just one Dynamco fitting, simplifying connections and minimizing cost.

Variety – Dynamco offers a full line of tees, elbows and connectors, allowing you to complete virtually any job with miniature sized tubing.

Tubing – Dynamco offers polyurethane tubing in black and clear colors. Two sizes of tubing are available. The smaller tubing (1/16" ID x 1/8" OD) is used for interconnection between logic components, for communication with power valve pilots and limit valves, and for all other connections not requiring a high flow. The larger tubing (1/8" ID x 1/4" OD) is used for control air supply lines and with valves