770

BONOMI NORTH AMERICA

STAINLESS STEEL SANITARY BALL VALVE

Stainless steel, 3-piece direct mount, sanitary full port ball valves with latch locking lever.

• ISO 5211 direct mount pad/square stem.

• Working pressure 1000 psi WOG (1/2” to 2”) 800 psi WOG (2 1/2” to 4”).

• Temperature range -20°F to 450°F.

• Blow-out proof stem.

• Antistatic Device.

• International polishing to Ra 15 micron.

• Tri-clamp style end connections.

• Ball valves comply with standards: ISO 5211, ANSI B 16.11, MSS SP-25, MSS SP-55.

• Maintenance free live loaded double sealing stem.

• Live loaded stem packing design.

770: NON-CAVITY FILLED - size 1/2” to 6”.

771: CAVITY FILLED - size 1/2” to 6”.

Choose your option

7700 LL

BONOMI NORTH AMERICA

STAINLESS STEEL BALL VALVE

Unibody stainless steel FNPT, seal welded threaded ball valve with locking handle, full port.

• Working pressure is 2000 psi (1/4” to 2”) - 200 psi steam.

• Temperature range -40°F to 450°F.

• Self-adjusting stem packing.

• Blow-out proof stem design.

• 100% air tested under water at 80 psi.

• Mounting pad for actuator.

• 25% carbon filled TFE seats.

• Graphite stem packing.

• API 607 certified.

• NACE MR 0175

7700LL: size 1/4” to 2”.

Choose your option

770V3-V6-V9 (NCF)

BONOMI NORTH AMERICA

Stainless steel direct mount 3 piece V-port ball valve with sanitary connections, sizes 1/2” to 4”.

• Highly polished internals and end caps with 8-12 Ra finish.

• A materials comply with FDA, USDA & 3A requirements.

• Investment cast body and end caps.

• ASTM 316 stainless steel.

• 100% tested and inspected prior to shippin.

• Full traceability of a components.

• SST x PTFE steam seats available for high temperature applications.

• Standard seats are 50% PTFE/50% SS.

• Cavity fillers are virgin PTFE.

Choose your option

771

BONOMI NORTH AMERICA

STAINLESS STEEL SANITARY BALL VALVE

Stainless steel, 3-piece direct mount, sanitary full port ball valves with latch locking lever.

• ISO 5211 direct mount pad/square stem.

• Working pressure 1000 psi WOG (1/2” to 2”) 800 psi WOG (2 1/2” to 4”).

• Temperature range -20°F to 450°F.

• Blow-out proof stem.

• Antistatic Device.

• International polishing to Ra 15 micron.

• Tri-clamp style end connections.

• Ball valves comply with standards: ISO 5211, ANSI B 16.11, MSS SP-25, MSS SP-55.

• Maintenance free live loaded double sealing stem.

• Live loaded stem packing design.

770: NON-CAVITY FILLED - size 1/2” to 4”.

771: CAVITY FILLED - size 1/2” to 4”.

Choose your option

771V3-V6-V9 (CF)

BONOMI NORTH AMERICA

Stainless steel direct mount 3 piece V-port ball valve with sanitary connections, sizes 1/2” to 4”.

• Highly polished internals and end caps with 8-12 Ra finish.

• A materials comply with FDA, USDA & 3A requirements.

• Investment cast body and end caps.

• ASTM 316 stainless steel.

• 100% tested and inspected prior to shippin.

• Full traceability of a components.

• SST x PTFE steam seats available for high temperature applications.

• Standard seats are 50% PTFE/50% SS.

• Cavity fillers are virgin PTFE.

Choose your option

772389

Live Centers - Speed Series

For very high speeds with an extended center point.

Special design for very high speeds with extended centre point and wear-resistant carbide insert. For counter-clamping workpieces on turning and grinding machines. Especially suitable for complex machining at high speeds.

Live centres- tip angle 60°, Mount MK 2, Size 752, extended NC-centre pointcarbide insert

Choose your option

772390

Live Centers - Speed Series

For very high speeds with an extended center point.

Special design for very high speeds with extended centre point and wear-resistant carbide insert. For counter-clamping workpieces on turning and grinding machines. Especially suitable for complex machining at high speeds.

Live centres- tip angle 60°, Mount MK 3, Size 753, extended NC-centre pointcarbide insert

Choose your option

772391

Live Centers - Speed Series

For very high speeds with an extended center point.

Special design for very high speeds with extended centre point and wear-resistant carbide insert. For counter-clamping workpieces on turning and grinding machines. Especially suitable for complex machining at high speeds.

Live centres- tip angle 60°, Mount MK 4, Size 754, extended NC-centre pointcarbide insert

Choose your option

772392

Live Centers - Speed Series

For very high speeds with an extended center point.

Special design for very high speeds with extended centre point and wear-resistant carbide insert. For counter-clamping workpieces on turning and grinding machines. Especially suitable for complex machining at high speeds.

Live centres- tip angle 60°, Mount MK 5, Size 755, extended NC-centre pointcarbide insert

Choose your option

776018 (L)

COMBI-SFER

STAINLESS STEEL 3-WAY BALL VALVE

Compact design, stainless steel, ANSI class 150 flanged 3-way ball valve.

• 3-way, diverter, two seats, L reduced port.

• Temperature range -4°F to 366°F.

• Blow-out proof stem.

• RPTFE seats, packing and thrust washer.

• 100% tested.

• TUV T.A. Luft approved.

• ISO 5211 mounting pad with double “D” stem.

776018: sizes 1/2” to 4”.

Choose your option

776032 (L)

SPLIT-BODY

CARBON STEEL 3-WAY BALL VALVE

Compact design, carbon steel, ANSI class 150 flanged 3-way ball valve. stainless steel ball and stem.

• 3-way, diverter, two seats, L reduced port.

• Temperature range -4°F to 366°F.

• Blow-out proof stem.

• RPTFE seats, packing and thrust washer.

• 100% tested.

• TUV T.A. Luft approved.

• ISO 5211 mounting pad with double “D” stem.

776032: sizes 1/2” to 6”.

Choose your option

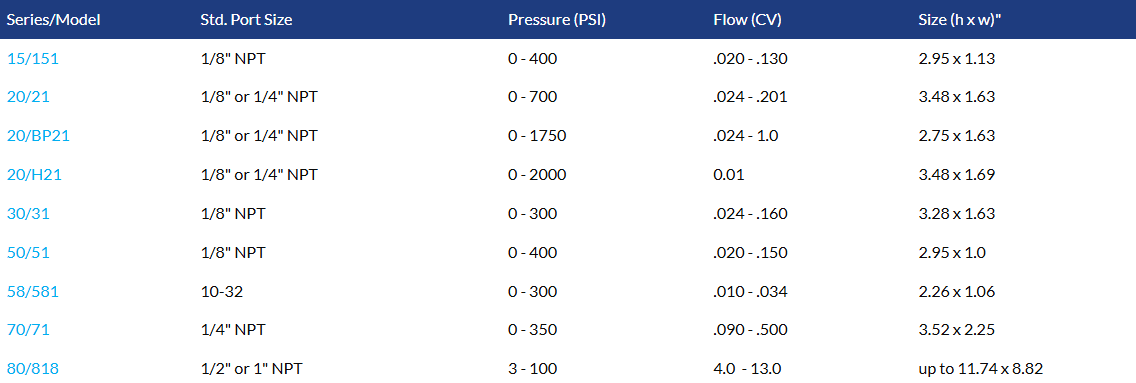

80/818

General Purpose 2-Way Normally Open Valves

PeterPaul general purpose solenoid valves offer a wide range of control options over the flow of liquids and gases in applications from dispensing to instrumentation, commercial equipment, machinery, medical/dental equipment, control systems and off-highway equipment, to name just a few.

Choose your option

80/828

General Purpose 2-Way Normally Closed Valves

PeterPaul general purpose solenoid valves offer a wide range of control options over the flow of liquids and gases in applications from dispensing to instrumentation, commercial equipment, machinery, medical/dental equipment, control systems and off-highway equipment, to name just a few.

Choose your option

80/829B

General Purpose 2-Way Normally Closed Valves

PeterPaul general purpose solenoid valves offer a wide range of control options over the flow of liquids and gases in applications from dispensing to instrumentation, commercial equipment, machinery, medical/dental equipment, control systems and off-highway equipment, to name just a few.

Choose your option

80/E828 C/I (HL)

Hazardous Location 2-Way Normally Closed Valves (C/I - Commecial/Industrial Gas Valve option available)

PeterPaul hazardous location valves are used where fire or explosion hazards exist due to the presence of flammable gases or vapors, flammable liquids, combustible dust, or easily ignitable fibers. Explosion Proof valves are recommended, or in some cases compulsory, where a high level of protection from explosion is required. For applications that require low power, a low watt version is also offered.

Choose your option

80/E828/OE22Z (HL)

Hazardous Location 2-Way Normally Closed Valves (C/I - Commecial/Industrial Gas Valve option available)

PeterPaul hazardous location valves are used where fire or explosion hazards exist due to the presence of flammable gases or vapors, flammable liquids, combustible dust, or easily ignitable fibers. Explosion Proof valves are recommended, or in some cases compulsory, where a high level of protection from explosion is required. For applications that require low power, a low watt version is also offered.

Choose your option

80/E829 C/I (HL)

Hazardous Location 2-Way Normally Closed Valves (C/I - Commecial/Industrial Gas Valve option available)

PeterPaul hazardous location valves are used where fire or explosion hazards exist due to the presence of flammable gases or vapors, flammable liquids, combustible dust, or easily ignitable fibers. Explosion Proof valves are recommended, or in some cases compulsory, where a high level of protection from explosion is required. For applications that require low power, a low watt version is also offered.

Choose your option

8100

HIGH PERFORMANCE BUTTERFLY VALVE

CARBON STEEL

Manually operated ANSI 150 class, high performance Wafer style butterfly valves.

• Temperature range -20°F to 446°F, 150 WSP.

• ISO 5211 direct mounting pad/square stem.

• Compact design, easy access to packing.

• Replaceable seat design.

• Multiple V-ring stem packing.

• RPTFE seats, metal seats upon request.

• 14” to 24” sizes available upon request.

• NACE MR0175.

• FC170-2 compliant.

• CRNs available upon request.

• 10 position locking handle.

• Soft seat leakage protection - Class VI.

• Metal seat leakage protection - Class V.

8100-9100: size 2” to 12”.

8120-9120: METAL SEATED VERSION - size 2” to 12”.

8140-9140: API 607 FIRE SAFE VERSION - size 2” to 12”.

G8100-G9100: GEAR OPERATED VERSION - size 2” to 12”.

Choose your option

8101

HIGH PERFORMANCE BUTTERFLY VALVE

CARBON STEEL

Manually operated ANSI 150 class, high performance Lug style butterfly valves.

• Temperature range -20°F to 446°F, 150 WSP.

• ISO 5211 direct mounting pad/square stem.

• Compact design, easy access to packing.

• Replaceable seat design.

• NACE MR0175.

• FC170-2 compliant.

• CRNs available upon request.

• Multiple V-ring stem packing.

• RPTFE seats, metal seats upon request.

• 10 position locking handle.

• Soft seat leakage protection - Class VI.

• Metal seat leakage protection - Class V.

• 14” to 24” sizes available upon request.

8101-9101: size 2” to 12”.

8121-9121: METAL SEATED VERSION - size 2” to 12”.

8141-9141: API 607 FIRE SAFE VERSION - size 2” to 12”.

G8101-G9101: GEAR OPERATED VERSION - size 2” to 12”.

Choose your option

8300

HIGH PERFORMANCE BUTTERFLY VALVE

CARBON STEEL

Manually operated ANSI 300 class, high performance Wafer style butterfly valves.

• Temperature range -20°F to 446°F, 150 WSP.

• ISO 5211 direct mounting pad/square stem.

• Compact design, easy access to packing.

• Replaceable seat design.

• NACE MR0175.

• FC170-2 compliant.

• CRNs available upon request.

• Multiple V-ring stem packing.

• RPTFE seats, metal seats upon request.

• 10 position locking handle.

• Soft seat leakage protection - Class VI.

• Metal seat leakage protection - Class V.

• 14” to 24” sizes available upon request.

8300-9300: size 2” to 12”.

8320-9320: METAL SEATED VERSION - size 2” to 12”.

8340-9340: API 607 FIRE SAFE VERSION - size 2” to 12”.

G8300-G9300: GEAR OPERATED VERSION - size 2” to 12”.